Understanding the basics: A guide to “bottom-up” hyper-local merchandise planning

Today’s retail require a more agile, continuous approach

Traditionally, when making decisions about how much product to produce, buy, allocate, and later rebalance, retailers used whatever data they had on hand to determine what sales performance they could expect.

Generally speaking, that data was historical data on the past sales performance of products or stores. Then, using traditional tools such as open-to-buys or WSSIs, retailers would use these estimates to make core decisions about their inventory planning. In other words, these decisions were high-level, generalized estimates usually being dispatched from HQ, and hence a “top-down” approach.

In this guide, we’ll explore why top-down approaches to merchandise planning are too rigid and overgeneralized for today’s complex retail landscape and the clear benefits of a more agile, bottom-up, or hyper-local approach.

The trouble with “top-down” approaches to merchandise planning

In the past, it made perfect sense to approach merchandise planning from the top down. Retailers had to use the data they had on hand and were able to collect and interpret with currently available tools. But no matter how good your data is, or how much of it you have, it’s only as good as the tools you use and the approaches you take.

A proliferation of online channels, swiftly changing demand, and a call for more sustainable practices mean that retailers need more efficiency and flexibility than ever, and top-down approaches are just too rigid to let retailers meet new challenges.

Out of touch with reality and unable to change course

A major issue with top-down approaches to merchandise planning is their distance from reality. By basing decisions on oversimplified data and then forcing them down on current merchandising execution, it’s a recipe for misalignment, especially when reality doesn’t unfold as expected.

For example, what happens when some external factor, be it bad weather or a global pandemic, keeps customers from heading to physical locations in the middle of the season? What if demand over your online channels suddenly picks up out of nowhere?

Top-down decisions taken months earlier don’t have “listening” capacity necessary for adjusting course as reality plays itself out. And this capability is essential for keeping up with the most subtle changes that occur because of their much bigger impact on the bottom line.

Overgeneralization leads to overcompensation

Since top-down approaches can’t measure subtle real-time changes in demand across a retailer’s network, how have they dealt with this uncertainty in the past?

In order to make sure they can meet demand wherever it appears, retailers using top-down approaches have overcompensated by producing, buying, and allocating in excess. The problem is that later in the season, excess stock leads to the common retail culprits of overflowing storage, heavy discounting, and worst of all, waste. Bad for the environment and bad for the bottom line.

6 advantages of “bottom-up” hyper-local merchandise planning

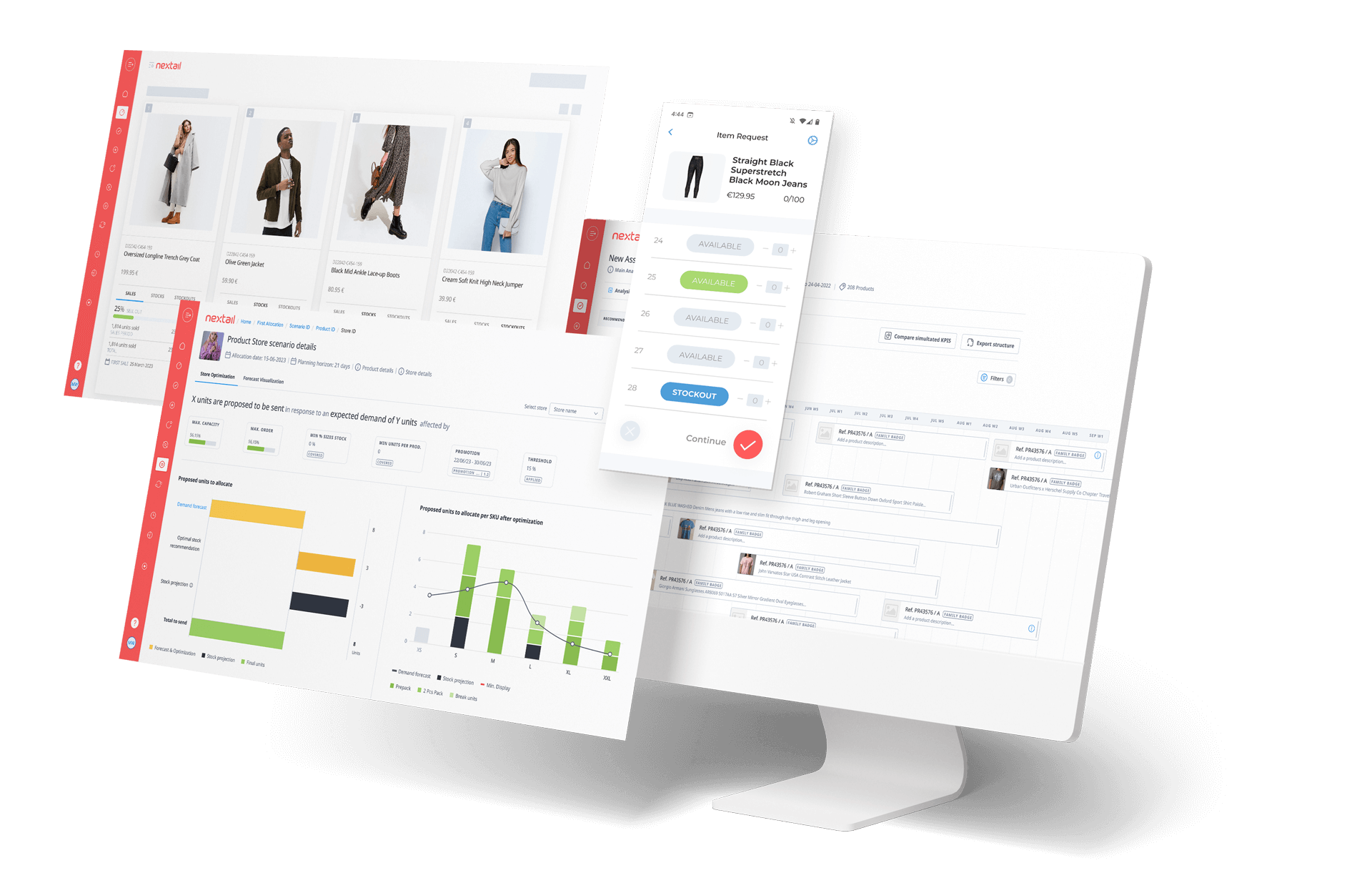

For flexible and agile merchandising operations, decision-making has to work the other way around. Advanced technologies like AI and predictive analytics make it possible to collect, manage and process the data necessary to account for the demand of each and every SKU-point of sale combination and feed that information upward for real-time decision-making.

Here are the 5 main benefits of a more agile approach to merchandise planning:

1. A firmer grasp on reality

Since you are able to track data on each and every SKU across your entire network, you are so much more aligned to the reality of demand and can capture changes and shifts and adapt to them faster.

So instead of buying products and trying to allocate them to the best of your ability based on potentially inaccurate data (the old approach), you can make allocation decisions based on what is selling right now, essentially decoupling the buying and allocation processes altogether.

This truer vision of the market enables you to make subtle and continuous changes to your assortments or even bigger decisions such as the strategy behind product introduction frequency, for example.

2. No need to rely on overgeneralizations

The nature of top-down decision-making is overgeneralized, simply because you’re trying to predict the future with very little actual information.

A bottom-up approach allows retailers to work with data at the most granular level. AI-driven approaches can take this a step further and actually aggregate this data considering business-specific requirements such as differing store capacities, visual merchandising requirements and more.

And since advanced machine learning algorithms allow you to constantly recalculate demand, groups of products and stores can be grouped and regrouped dynamically so you don’t get stuck allocating to fixed clusters.

3. Stronger forecasts and predictions

The more granular the data you are able to collect and process over time, the stronger forecasts and predictions will become when applying machine learning algorithms such as predictive analytics. Of course, the more confidence you have in these predictions, the more likely you are to change strategy if necessary.

4. Unified visibility of performance across channels

Bottom-up merchandise planning also makes it possible to gain visibility of performance across your entire network, including physical stores, online channels, and even warehouses. By centralizing this information, your whole team is privy to insights, and not just limited to one part of your business or another.

Learn how Nextail Sales KPIs and Inventory Analytics enable fashion retailers to track inventory and sales data across entire networks and optimize ongoing season performance.

5. Enhanced customer-centricity

Simply put, a good customer experience depends on the availability of the products that customers want to buy. Since each store and channel profile is different and continually changing, you must be able to detect even the most subtle differences in demand. With an agile retail methodology of this type, you can make continuous, hyper-local assortment decisions, putting customer demands at the very center of your strategy.

6. More sustainable operations

With a more efficient, less generalized approach to merchandise planning, retailers are able to increase their sustainability by confidently reducing safety stock and by ending up with less excess stock at the end of the season.

Whether this benefit is intentional or simply a positive consequence of working with more agility when it comes to their inventory, next-generation solutions that take a bottom-up approach are able to embed sustainability into their core merchandising operations. With Nextail specifically, they can reduce order volumes by 20% while lowering stock-outs by 60%.

If you’re ready to take the next step in transforming your fashion retail operations, here are 7 essential considerations for what to look for in a merchandise planning platform.