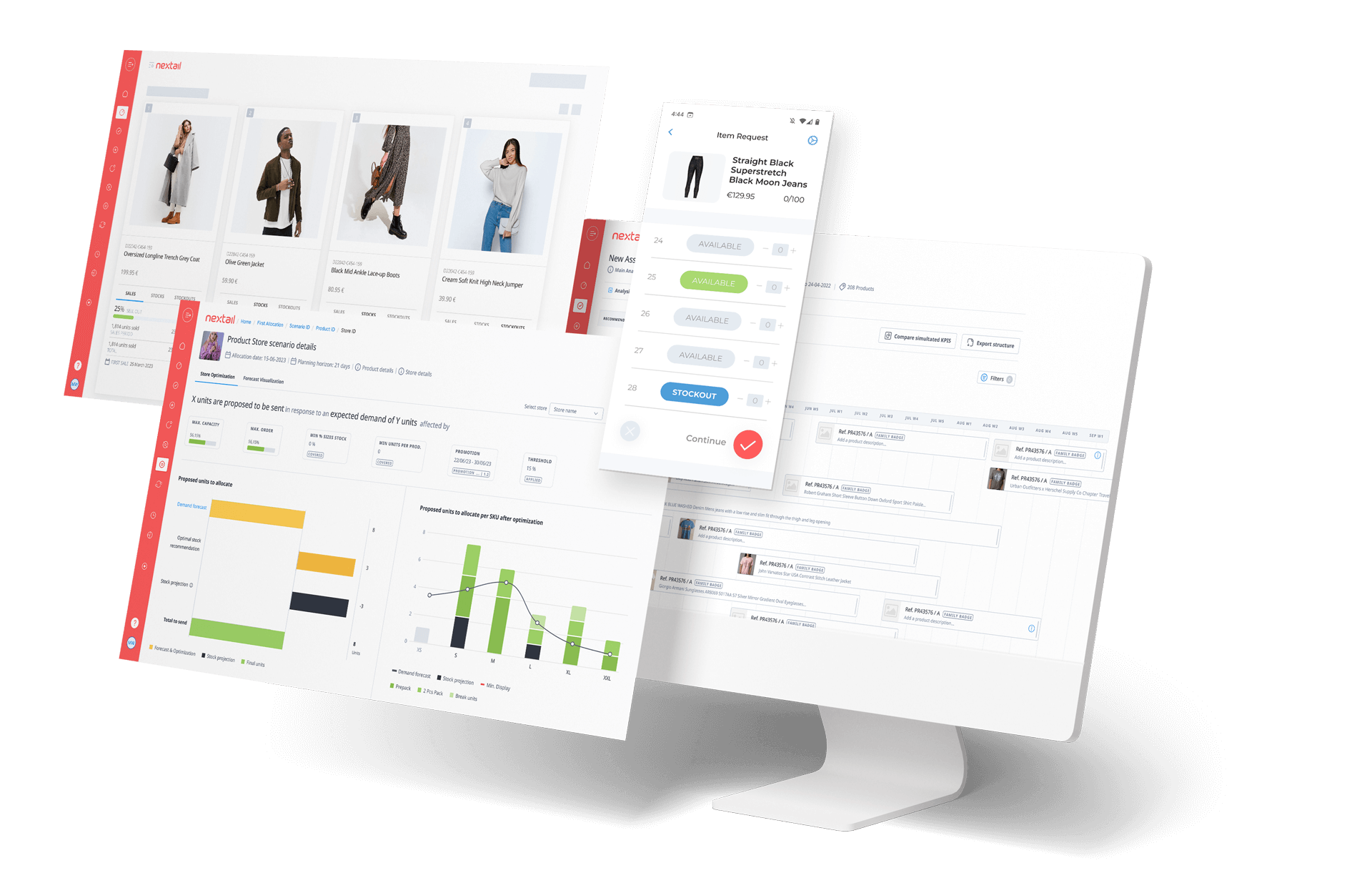

Hackett London partners with Nextail for an instant revenue impact

Just two months after implementing Nextail merchandise planning solutions, not only did the quintessential British men’s outfitter see rapid growth, their team was immediately empowered through more time for value-added tasks. What’s more, increased merchandising agility and efficiency are increasing the sustainability of the Hackett London’s operations.

Impact at a glance:

less time

on replenishments

fewer

international transfers

months =

double-digit growth

Why Nextail?

Hackett London: Heritage style with data-driven goals

Hackett London has over 150 stores in more than 30 countries. The premium multi-channel brands sits at the forefront of traditionally-inspired menswear, defined by excellence and craftsmanship. But manual and tedious approaches to their merchandising processes were time-consuming, inefficient, and susceptible to human error.

Hackett London sought a partner that could help them:

- Increase full-price sell-through

- Reduce in-store coverage

- Give merchandisers back more time to dedicate to creative and strategic tasks

Hackett London chose Nextail thanks to the successful results of another AWWG brand that had drastically increased efficiency by leveraging AI and machine learning to automate decision-making related to their merchandise planning processes.

“Looking at like-for-like data, within two months, we saw double-digit growth across Nextail-managed stores.”

Impact

Shortly after go-live with the Nextail Replenishment solution, both Hackett London’s pre- and main collections saw increasingly improved sell-through rates at the same time coverage was dropping, all while maintaining healthy stockout levels.

Forecasting and running simulations became faster and less prone to “bad data” or filing errors. And since Nextail can spot data anomalies, which teams can confirm later, they can be excluded from forecasting.

Empowered by a strong demand forecast that delivers optimized replenishment and store transfer decisions, Hackett London has been able to reduce the number of shipments from Barcelona to the UK by 50% each week.

“As specialists in their area, we might tell some store managers what they need based on the data. But they have the autonomy to come to us and say ‘I know what the data says, but please give me the opportunity to overperform’. So we’re informed by the objective data and still have the power to be creative.”