The hidden costs of inefficient replenishment logic

It is an undisputed truth of retail that one of the industry’s hardest problems is making sure that the right product is present in the right store, at the right time; so that a stochastic event like a sales transaction can take place. It is therefore surprising how many retailers still rely on logic — and systems — founded in the past to drive such a core operational business process, which has critical impact on business performance and profitability.

“Sell One-Send One” replenishment shortfalls

In this post I analyse the most basic replenishment algorithm: “sell one-send one”. With a fixed frequency, e.g. weekly, the algorithm will look at a certain period in the past, e.g. the past 7 days, and decide to replenish for every SKU-store the exact same amount that has been sold in the past period.

This algorithm is decisively simple, and can be implemented with the help of a simple spreadsheet… or even, pen and paper. In fact, many ERPs or POS provide such algorithms.

Challenge 1: Observable Sales

The ‘Sell One-Send One’ algorithm is restricted to observable sales, which only partially correlate with actual demand. Sales are a stochastic process and therefore follow a random probability pattern that can be analysed statistically but cannot be predicted precisely. Moreover, sales are limited by store product availability (i.e. stock-outs) so there is an unmet demand that is not being taken into consideration. This means that any mistake made in the initial decision of how much to send to the store in the “First Allocation” will sentence a retailer to an entire season of uninterrupted bad decisions over that product!

Basic replenishment systems create a self-fulfilling prophecy in which stores in best-selling clusters will receive larger assortments, will sell more throughout the campaign, and the next season the same story of bad decisions will start all over again.

Challenge 2: Past sales as a predictor of the future

This algorithm is backward-looking; and, as we know, the past might not be a good predictor of the future. Retail sales are highly variable from one period to the next, due to a multitude of factors, some of which might be under the retailer’s control (pricing & promotions, marketing activity), while others are external (seasonality, holidays, weather conditions). The algorithm will always maintain the same stock levels, unable to adapt even to the most foreseeable changes in demands.

Challenge 3: Data accuracy

This algorithm is very sensitive to inaccurate data. If you have stores that have problems “sending” the sales data to the head office, they won’t be replenished, which might lead to stockouts and lost sales. And, based on our experience, it is still common for stores to have network issues that prevent sales data from being updated in real time.

Challenge 4: Lead time

The ‘sell one-send one’ approach doesn’t take into consideration the differences in delivery times across the retail network. Take an extreme example of a store in a remote area where it takes 2 weeks of transportation lead time, whatever quantity is being calculated today will take 2 weeks to arrive. During that period the store will be selling stock that the replenishment system has not accounted for.

Challenge 5: All stores treated equally

Fast fashion, among other trends, has increased the rotation of items while reducing assortment depths, making products more and more scarce. When warehouse product availability starts to diminish, there is no logic of prioritising the stores with the highest probability of selling those precious last units.

Conclusion

Basic replenishment algorithms like the one described still drive the inventory decisions of many fashion retailers.

The result is well known: overstocks in some stores, stock-outs in others, low sell-through and sell-out rates, and big end of season leftover quantities. And, more importantly, a lot of unsatisfied customers because they couldn’t find what they wanted.

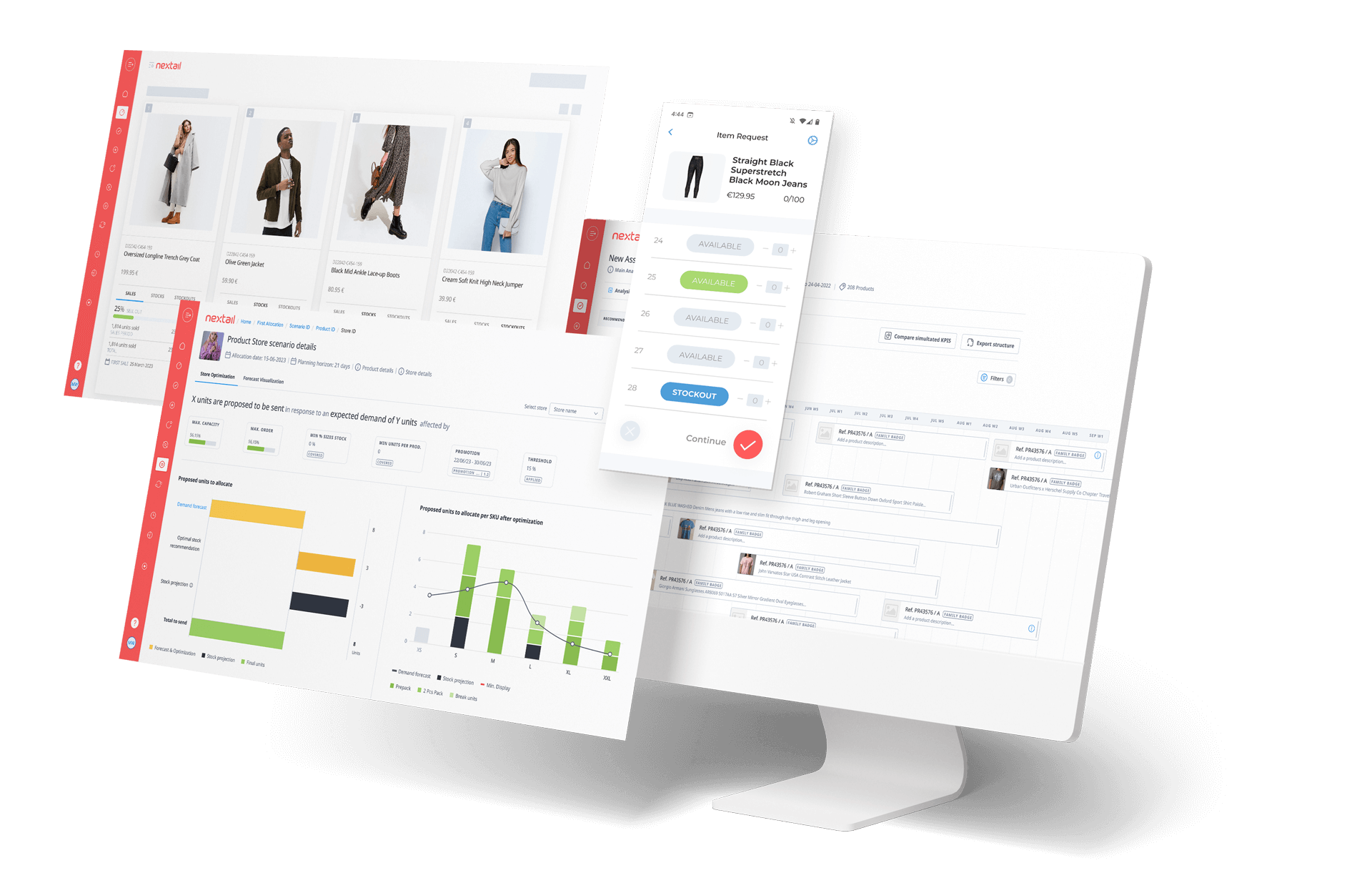

The only advantage of this traditional algorithm, its low cost, is also progressively being eroded. Thanks to advances in data science and the price reduction of computing power (Moore’s law is now more present than ever), the full power of predictive analytics and multi-variable profit optimisation models are available to any retailer for a very competitive price. With easy integration into existing ERPs, and direct impact on financial KPIs, the return on investment of these advanced methods is incredible.