Gina Tricot makes gains on sustainability through merchandising innovation and efficiency

The Swedish womenswear retailer offers the latest styles in over 30 countries and through approximately 150 stores across Sweden, Norway, Finland and Denmark as well as via e-commerce across Europe. Gina Tricot is a great example of a forward-thinking international fashion brand that is always looking to evolve and is dedicated to seeking sustainable solutions, creative working ideas, and unique collaboration opportunities to deliver on its promise to “make women smile”.

Impact at a glance

lower

store cover

fewer

store stockouts

sell-through

increase

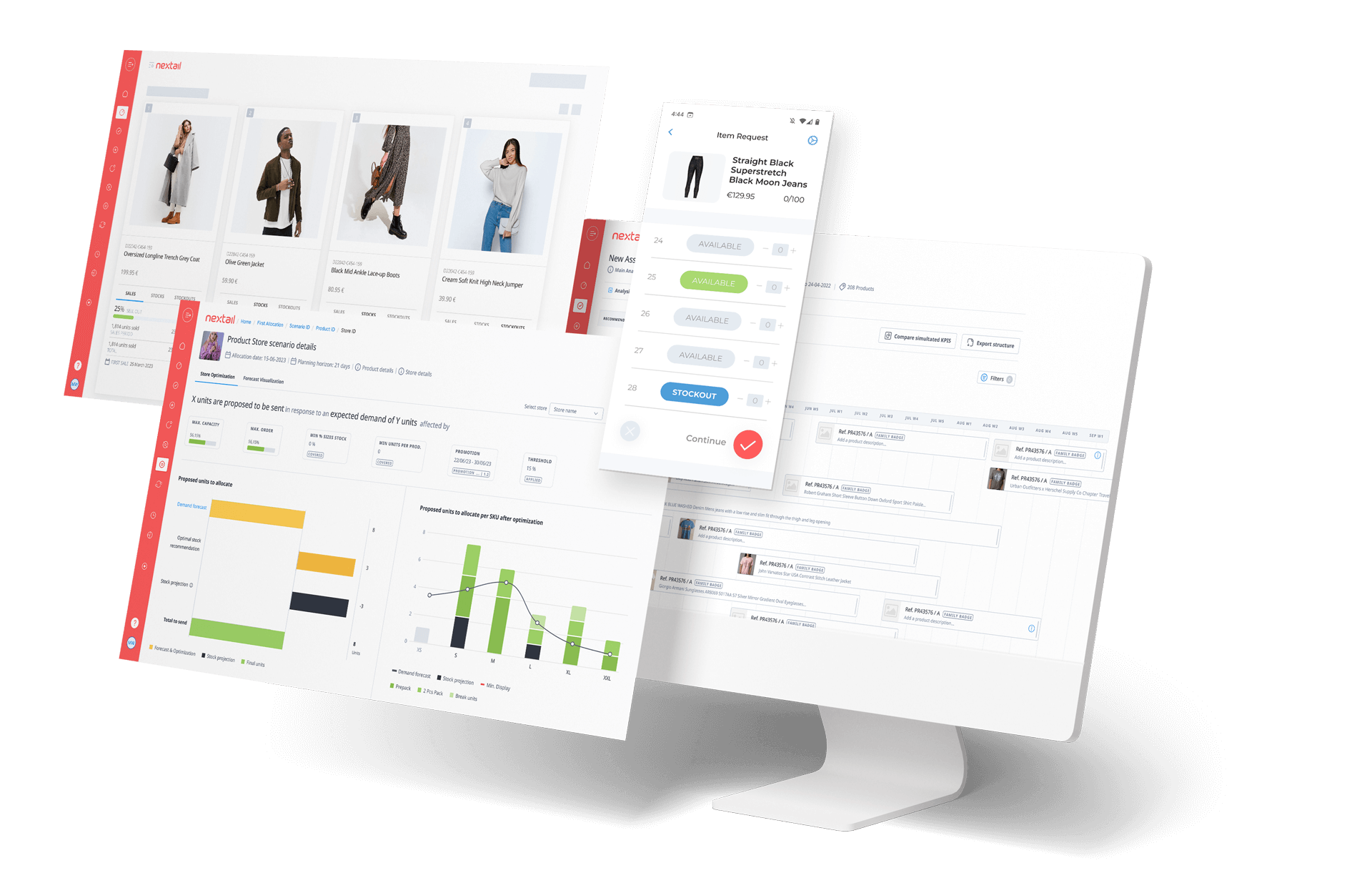

Why Nextail?

Fashion know-how for embedding efficiencies & sustainability into merchandising operations

Gina Tricot sought a partner that would help them alleviate specific challenges they were facing related to core merchandising operations, specifically to:

- Allocate and replenish more strategically by way of intelligent, data-driven demand forecasting

- Improve sell-through to reduce overproduction, end-of-season waste, and missed sales opportunities

- Increase the efficiency of teams and reduce time spent on manual tasks

Gina Tricot chose Nextail as the partner to help build agility and sustainability into the business due to the strength of its merchandise planning solutions as well as the Nextail team’s deep domain expertise in fashion and change management.

“Nextail emerged as the ideal partner for Gina Tricot as their merchandise planning platform not only enables us to work more efficiently but also contributes to our sustainability commitments. By leveraging data driven insights and the team’s deep fashion and retail expertise, we are learning to produce less while also creating truly customer-driven assortments.”

Impact

Gina Tricot can now allocate smaller amounts of products to stores and replenish based on early performance indicators and real consumption, sending them to stores with the highest full-price demand for each item.

Intelligent allocation and automated replenishment in combination with inventory rebalancing later in the season has also had a positive impact on product availability and business results.

By incorporating efficiencies and automation, the Gina Tricot allocation team has been able to cut the time spent on replenishment processes in half.

“We’re delighted to work with a team at Nextail that genuinely values the success of our project and business. Nextail has helped us overcome both tangible and intangible challenges of the change management process and we look forward to seeing how this transformation will shape our future merchandising strategies.”